Univ. of Washington unveils plans for lab space dedicated to battery innovation

Entrepreneurs and academics worldwide are trying to figure out how far innovation can stretch the power and performance of batteries.

Since 2017, the Washington Clean Energy Testbeds at the University of Washington have provided a space, tools and expertise to support that work for startups and university staff and students. Today the facility’s leaders are unveiling plans for an open-access lab that will allow researchers to validate their new technologies by incorporating them into custom-made pouch cell batteries.

“A battery is a chemical system that is highly engineered so that all the parts work together,” said Dan Schwartz, founding director of the UW’s Clean Energy Institute, which includes the testbeds. “And the nation is really under-invested in that kind of engineering work.”

Here’s the challenge. Researchers often tackle one component of a battery’s system for optimization, such as the chemistry of an anode. But they need to demonstrate how their solution performs with the rest of the ingredients if they want to prove its benefits.

The new lab will provide that missing piece in the engineering infrastructure.

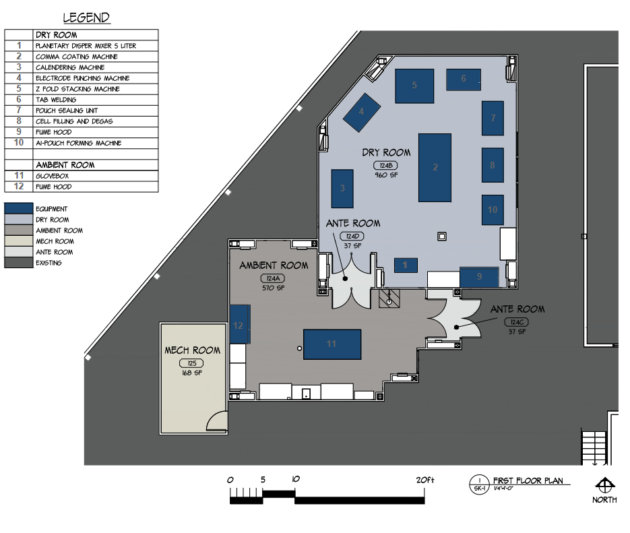

The facility will have a dry room and equipment for creating electrode slurries, coating electrodes, and layering the battery components. The batteries will be fabricated in plastic-lined aluminum pouches that bear a resemblance to a Pop Tart package.

While useful for experiments, the pouch cell batteries also have commercial applications in electric vehicles and consumer electronics. Schwartz said there’s growing demand for the pouch cell batteries from heavy trucking and aviation.

“There’s flexibility to build designs that are optimized for all kinds of different use cases,” he said. “And this is at the scale that you can test it.”

The new 1,600-square-foot lab expansion will involve repurposing some storage space inside the current 15,000-square-foot testbed facility, located just east of the UW’s main Seattle campus. It’s scheduled to open next summer.

The project will cost $7.5 million. The money is coming from the state’s Climate Commitment Act, a program supporting the clean energy transition that could be eliminated if Initiative 2117 passes next month.

The industry has been clamoring for these new resources, Schwartz said. In the past seven years, 150 clean tech companies have used the testbeds for work on batteries, solar energy, the electrical grid and other technologies. Battery alumni include Group14 Technologies and Ecellix, two Washington companies that have developed silicon-carbon materials that replace graphite in battery anodes.

“These new prototyping capabilities at the Testbeds are filling a critical need for battery innovation infrastructure in the U.S.,” said Rick Luebbe, Group14’s CEO and co-founder, in a statement.

Group14 has raised more than $650 million from investors and is building in Eastern Washington what could become the world’s largest manufacturing facility for silicon anode materials.

As battery businesses grow their operations, there’s also an increasing need for skilled workers. The UW in January is launching a Graduate Certificate in Battery Engineering, which will include workshops at the Testbeds and be offered to students at two-year schools around Washington.

In a few years, the entire Clean Energy Testbeds will be moving to a new building called Brightwork, which will be part of a bigger UW initiative called the Portage Bay Crossing. Construction was supposed to start this year and take about two years to complete, but the developers have not yet broken ground.

Schwartz said their labs are designed to be able to pack up and move. And with more demand for better batteries, the pouch cell lab couldn’t wait on a new building.

“This is a field that can’t go slow,” Schwartz said.